ABOUT US

Steel processing

News

Download

Contact us

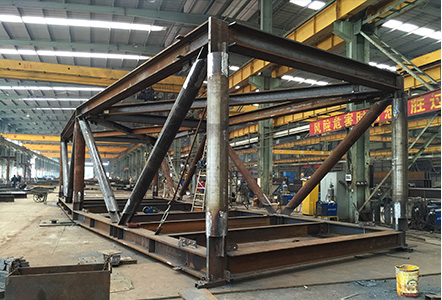

Steel structure machining

Structural steel machining refers to cutting, bending and assembling steel to create different products. Structural steel parts are joined together by welding or bolting, and during the processing of steel structures, several pieces of steel are combined together to form a structure of a certain size and shape for assembly into buildings, industrial equipment, tools, and various other final in the product.

Huang Shangyou specializes in the fabrication and installation of various types of structures in Hong Kong, and is committed to providing reliable and high-quality services to our customers in an efficient and economical way.

Huang Shangyou specializes in the fabrication and installation of various types of structures in Hong Kong, and is committed to providing reliable and high-quality services to our customers in an efficient and economical way.

Advantages of steel structure

Steel structures are malleable and can be customized to project specifications.

Steel structures usually arrive on site during the prefabrication stage and are fabricated on site. Prefab reduces the amount of work that needs to be done on site, making it easy to fast track projects.

Steel construction offers excellent durability and strength, and its metallurgical properties allow it to be easily fabricated into any shape and size.

Steel structures usually arrive on site during the prefabrication stage and are fabricated on site. Prefab reduces the amount of work that needs to be done on site, making it easy to fast track projects.

Steel construction offers excellent durability and strength, and its metallurgical properties allow it to be easily fabricated into any shape and size.

Hot dip galvanized permanent steel beams

Hot dip galvanized permanent steel beams Hot dip galvanized truss

Hot dip galvanized trussCharacteristics of steel structures

Steel construction is an alloy whose physical and mechanical properties can be adjusted as needed.

Steel structures are used to construct buildings, bridges, vehicle parts and household appliances. In manufacturing, steel structures are used to produce platforms, steel ladders, industrial stairs, mezzanines, steel handrails, etc.

Steel structures are used to construct buildings, bridges, vehicle parts and household appliances. In manufacturing, steel structures are used to produce platforms, steel ladders, industrial stairs, mezzanines, steel handrails, etc.

Steel structure flyover

Steel structure flyover LED display steel structure

LED display steel structureSteel structure processing technology

Our fabrication team has the full range of skills required for a steel fabrication project, including:

Crack and Weld Defect Repair:Pre-weld heat treatment, post-weld heat treatment, gouging, trench filling, temperature-induced stress homogenization

Non-destructive testing (NDT testing):Magnetic Particle Inspection (MPI), X-ray Photography Inspection, Dyeing Inspection (DPI), Ultrasonic Thickness Measurement

Steel processing:Bending, drilling, punching, punching, steel cutting by plasma, oxygen, laser, bevel, sand saw, grinding

Welding treatment:Partial penetration, full penetration, fillet welds

On-site and off-site welding:Shop Welding – Pulse MIG, MIG, TIG, MMA, Field Welding – MMA, MIG Diesel Welders

Surface treatment:Grinding off paint, wire polishing rust, sandblasting, polishing and sanding

Anticorrosion:Hot dip galvanizing, powder coating, paint

Assembly:Workshop trial

Crack and Weld Defect Repair:Pre-weld heat treatment, post-weld heat treatment, gouging, trench filling, temperature-induced stress homogenization

Non-destructive testing (NDT testing):Magnetic Particle Inspection (MPI), X-ray Photography Inspection, Dyeing Inspection (DPI), Ultrasonic Thickness Measurement

Steel processing:Bending, drilling, punching, punching, steel cutting by plasma, oxygen, laser, bevel, sand saw, grinding

Welding treatment:Partial penetration, full penetration, fillet welds

On-site and off-site welding:Shop Welding – Pulse MIG, MIG, TIG, MMA, Field Welding – MMA, MIG Diesel Welders

Surface treatment:Grinding off paint, wire polishing rust, sandblasting, polishing and sanding

Anticorrosion:Hot dip galvanizing, powder coating, paint

Assembly:Workshop trial

Steel structure manufacturing process

NDT detection

NDT detection Steel structure product transportation

Steel structure product transportationSteel structure engineering case

Temporary bridge project for CLP cables and communication pipelines

Temporary bridge project for CLP cables and communication pipelines Construction of Kai Tak Station Plaza (Phase 1)

Construction of Kai Tak Station Plaza (Phase 1) Hong Kong-Zhuhai-Macao Bridge – Hong Kong Immigration Department Hardcover Project

Hong Kong-Zhuhai-Macao Bridge – Hong Kong Immigration Department Hardcover Project Get Your Free Quotation Today!

HK HuangShangYou Steel Industrial Limited

HK HuangShangYou Steel Industrial LimitedEmail: king@ulsteel.com WhatsApp: +852-65561469 WeChat: +852-65561469

[contact-form-7 id=”2011″ title=”pr-contact”]

相關產品

2012-2024 HSY Steel All Rights Reserved.