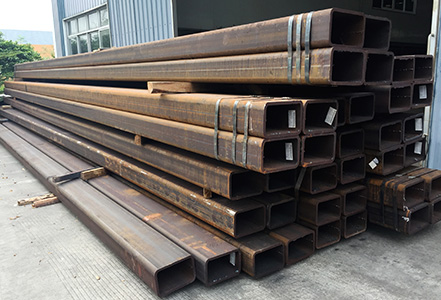

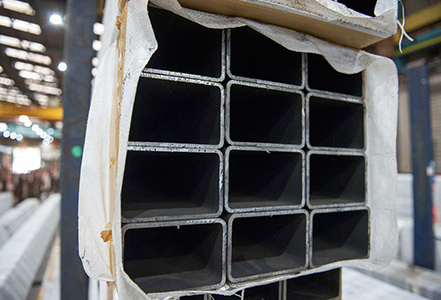

Cold-Formed Structural Rectangular Steel Pipe (RHS) is manufactured from hot rolled coil with a smooth surface and raised internal welds. These tubes give up weldability and greater strength and are often used as structural parts.

For joining and various other types of fabrication work, flat surfaces are the more economical solution, so rectangular steel pipes are a popular choice for mechanical, structural and architectural applications. The shape of rectangular steel pipe is easy to weld, cut, form and machine.

S235JRH Cold Formed Rectangular Steel Pipe:High durability, good electrical conductivity, excellent ductility, forming and welding performance. With high tensile strength and precise dimensions, it is very corrosion resistant and can be used in mining and excavation industrial applications.

S275J2H Cold Formed Rectangular Steel Pipe:With high yield strength and high mechanical resistance, it is used as fixed load-bearing structure in civil engineering and construction. Due to its static advantages, this flat pass is very suitable for mechanical engineering. It is also used in the automotive industry and aerospace.

S355J0H Cold Formed Rectangular Steel Pipe:Welding can be performed without intergranular corrosion. High tensile strength, heat and corrosion resistance, strong and easy to install, suitable for machinery manufacturing, steel construction engineering, shipbuilding, solar support, steel structure engineering, power engineering, etc. It is also an ideal choice for infrastructure development, petrochemical, boiler manufacturing and other industries.

S355J2H Cold Formed Square Tube:Good strength, high tensile strength, inherently toughened, easy to remove and install, perform well in any temperature range.

The available grades of rectangular steel pipes are EN, ASTM, GB and JIS.

The section size of the cold-formed structural rectangular steel pipe can reach 800mm and the thickness can reach 35mm. The normal supply length is 6m~12m, but other lengths of 4m~16m can be provided upon request. Additionally, other lengths are available upon request. This meets almost all international quality standards and undergoes various tests.

Steel pipe implementation standard:EN 10219-2 : 2006

鋼管材質等級:S235JRH,S275J0H,S275J2H,S355J0H,S355J2H,S275NH,S420MH,S460MH, IS 4923 / ASTM A500

Surface Protection: Black (Natural Uncoated), Clear/Oil Coated, Pre-Galvanized, Hot-Dip Galvanized

Metal slings are generally bundled into rectangles for storage and transportation.

European Standard BS EN 10219-2: 2006

| size(D x B) | thickness(t) | unit weight |

| mm | mm | kg/m |

| 40 x 20 | 2.0 | 1.68 |

| 3.0 | 2.36 | |

| 50 x 25 | 2.0 | 2.15 |

| 2.5 | 2.62 | |

| 3.0 | 3.07 | |

| 50 x 30 | 2.0 | 2.31 |

| 2.5 | 2.82 | |

| 3.0 | 3.30 | |

| 4.0 | 4.20 | |

| 60 x 30 | 3.0 | 3.77 |

| 4.0 | 4.83 | |

| 60 x 40 | 2.0 | 2.93 |

| 2.5 | 3.60 | |

| 3.0 | 4.25 | |

| 4.0 | 5.45 | |

| 5.0 | 6.56 | |

| 70 x 40 | 3.0 | 4.72 |

| 4.0 | 6.08 |

| grade | The chemical composition is not more than Max.(%) | |||||

| C | Si | Mn | P | S | N | |

| S235JRH | 0.17 | — | 1.4 | 0.040 | 0.040 | 0.009 |

| S275J0H | 0.20 | — | 1.5 | 0.035 | 0.035 | 0.009 |

| S275J2H | 0.20 | — | 1.5 | 0.030 | 0.030 | — |

| S355J0H | 0.22 | 0.55 | 1.6 | 0.035 | 0.035 | 0.035 |

| S355J2H | 0.22 | 0.55 | 1.6 | 0.030 | 0.030 | — |

| grade | The chemical composition is not more than Max.(%) | |||||||||||

| C | Si | Mn | P | S | Nb | V | Al (Min.) |

Ti | Ni | Mo | N | |

| S275MH | 0.13 | 0.50 | 1.50 | 0.035 | 0.030 | 0.050 | 0.08 | 0.020 | 0.050 | 0.30 | 0.20 | 0.020 |

| S275MLH | 0.030 | 0.025 | ||||||||||

| S420MH | 0.16 | 0.50 | 1.70 | 0.035 | 0.030 | 0.050 | 0.12 | 0.020 | 0.050 | 0.30 | 0.20 | 0.020 |

| S420MLH | 0.030 | 0.025 | ||||||||||

| grade | Yield strength not less than Min.(N/mm2) | tensile strength(N/mm2) | |||||||

| t≤16 | 16<t≤40 | 40<t≤63 | 63<t≤80 | 80<t≤100 | 100<t≤120 | t≤3 | 3<t≤100 | 100<t≤120 | |

| S235JRH | 235 | 225 | 215 | 215 | 215 | 195 | 360~510 | 360~510 | 350~500 |

| S275J0H | 275 | 265 | 255 | 245 | 235 | 225 | 430~580 | 410~560 | 400~540 |

| S275J2H | |||||||||

| S355J0H | 355 | 345 | 335 | 325 | 315 | 295 | 510~680 | 470~630 | 450~600 |

| S355J2H | |||||||||

| S275MH | 275 | 265 | — | — | — | — | 360~510 | 360~510 | — |

| S275MLH | |||||||||

| S420MH | 420 | 400 | — | — | — | — | 500~660 | 500~660 | — |

| S420MLH | |||||||||

| grade | The elongation is not less than Min.(%) | Minimum impact energy KV(J) | ||||||

| t≤40 | 40<t≤63 | 63<t≤100 | 100<t≤120 | -50℃ | -20℃ | 0℃ | +20℃ | |

| S235JRH | 26(24) | 25 | 24 | 22 | — | — | — | 27 |

| S275J0H | 23(20) | 22 | 21 | 19 | — | — | 27 | — |

| S275J2H | — | 27 | — | — | ||||

| S355J0H | 22(20) | 21 | 20 | 18 | — | — | 27 | — |

| S355J2H | — | 27 | — | — | ||||

| S275MH | 24 | — | — | — | — | 40 | — | — |

| S275MLH | 27 | — | — | — | ||||

| S420MH | 19 | — | — | — | — | 40 | — | — |

| S420MLH | 27 | — | — | — | ||||

HK HuangShangYou Steel Industrial Limited

HK HuangShangYou Steel Industrial LimitedEmail: king@ulsteel.com WhatsApp: +852-65561469 WeChat: +852-65561469