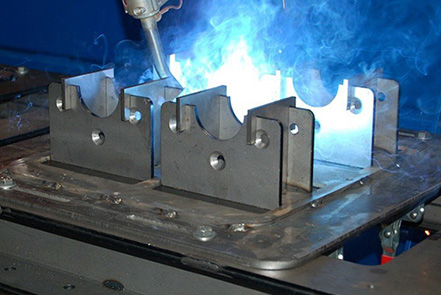

All equipment configurations in the welding processing factory are configured according to the requirements of automatic welding of batch products. The models of welding equipment are relatively comprehensive, ranging from 25 watts, 75 watts, 300 watts, 500 watts, and 2500 watts. From YAG pulse laser welding Machine to fiber laser laser welding machine, all are optical fiber transmission laser welding machines, including almost all the equipment required for spot welding, high-speed welding, and precision seamless continuous welding. The processed products cover ultra-small, ultra-fine, ultra-thin, Ultra-precision to long welds, three-dimensional welding, to large boxes, thick sheet metal;

The welding method can be butt welding of two workpieces or plates, penetration welding of two workpieces stacked together, rotary welding of circular workpieces, spot welding of sheet stamping parts, deep penetration welding of thick plate products, straight seam welding of sheet metal products, Single-sided welding and double-sided forming welding, double-mirror stainless steel seamless welding, non-damage welding of appearance products, no heat-affected welding of electronic packages, pressure-bearing welding of pressure products, argon arc welding, gas shielded welding, flaw detection welding, flying welding, etc.;

Welding service

Welding service Welding service

Welding serviceWide applicability, welding is suitable for the connection of various metal materials, including steel, copper, aluminum, magnesium, etc., and can realize the splicing and repairing of various complex parts;

The connection is firm, the welding seam of welding process has high strength and good sealing performance, which can ensure the firmness of the connection of parts;

The processing cost is low. Compared with other processing methods, the processing cost of welding is relatively low, because it does not require special equipment and tools, and only needs some simple welding tools to complete;

High processing flexibility: welding can be carried out in different working environments and positions, with wide applicability and flexible adjustment of processing schemes.

HK HuangShangYou Steel Industrial Limited

HK HuangShangYou Steel Industrial LimitedEmail: king@ulsteel.com WhatsApp: +852-65561469 WeChat: +852-65561469