ABOUT US

Steel processing

News

Download

Contact us

Hot dip zinc profiles

Hot dip galvanizing is a unique process. When clean steel is immersed in molten zinc, a metallurgical reaction between iron and zinc forms a series of zinc-iron alloy layers that provide the strong coating that is an integral part of steel.

The zinc-iron alloy layer formed by hot-dip galvanizing not only forms a barrier between the profile and the environment, but also acts as a cathodic protection for the profile. The cathodic protection provided by zinc means that the galvanized coating sacrifices itself to protect the underlying substrate from corrosion. The sacrificial nature of the coating results in a durable high-quality profile.

For over 100 years, hot-dip galvanized profiles have been widely used for corrosion protection in agricultural, solar, automotive, construction, and industrial environments, including petrochemicals, transportation, and utilities.

The zinc-iron alloy layer formed by hot-dip galvanizing not only forms a barrier between the profile and the environment, but also acts as a cathodic protection for the profile. The cathodic protection provided by zinc means that the galvanized coating sacrifices itself to protect the underlying substrate from corrosion. The sacrificial nature of the coating results in a durable high-quality profile.

For over 100 years, hot-dip galvanized profiles have been widely used for corrosion protection in agricultural, solar, automotive, construction, and industrial environments, including petrochemicals, transportation, and utilities.

Hot dip galvanized square pass

Hot dip galvanized square pass Hot dip galvanized H-beam

Hot dip galvanized H-beamAdvantages of hot dip galvanized profiles

1. The initial cost of hot-dip galvanized profiles is lower than most treated steels. In addition, the galvanized steel is ready for use upon delivery.

2. A major advantage of hot-dip galvanized profiles is their durability. Surface coatings provide both physical and cathodic protection, with a high level of corrosion protection, steel structures or components typically reach their design life without maintenance, even when exposed to harsh environments, reducing maintenance budgets.

3. Due to its unique metallurgical combination, the galvanized coating is very tough, so galvanized steel has excellent resistance to mechanical damage during handling, storage, transportation and installation.

4. The metallurgical reaction that takes place between zinc and steel is a diffusion process, which means that the coating increases perpendicular to all surfaces, so the galvanized layer at the corners and edges is at least as thick as the rest of the item. In addition, since hot-dip galvanizing is a full-dip process, the hollow structure is coated on the inside and outside.

2. A major advantage of hot-dip galvanized profiles is their durability. Surface coatings provide both physical and cathodic protection, with a high level of corrosion protection, steel structures or components typically reach their design life without maintenance, even when exposed to harsh environments, reducing maintenance budgets.

3. Due to its unique metallurgical combination, the galvanized coating is very tough, so galvanized steel has excellent resistance to mechanical damage during handling, storage, transportation and installation.

4. The metallurgical reaction that takes place between zinc and steel is a diffusion process, which means that the coating increases perpendicular to all surfaces, so the galvanized layer at the corners and edges is at least as thick as the rest of the item. In addition, since hot-dip galvanizing is a full-dip process, the hollow structure is coated on the inside and outside.

Hot dip galvanized channel steel

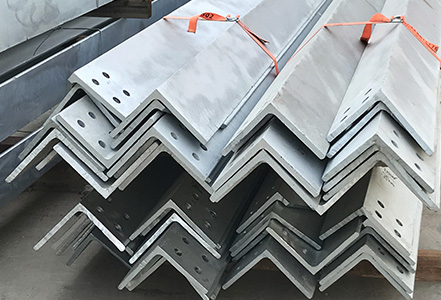

Hot dip galvanized channel steel Hot dip galvanized angle steel

Hot dip galvanized angle steelSteps of hot dip galvanizing

1. Clean the steel in a degreasing solution

2. After cleaning, put the steel in a bucket of diluted hot sulfuric acid for pickling

3. Flux the steel in an aqueous solution (usually zinc ammonium chloride)

4. After the flux, the steel is dipped into a molten zinc bath for galvanizing

5. Check the finished product

2. After cleaning, put the steel in a bucket of diluted hot sulfuric acid for pickling

3. Flux the steel in an aqueous solution (usually zinc ammonium chloride)

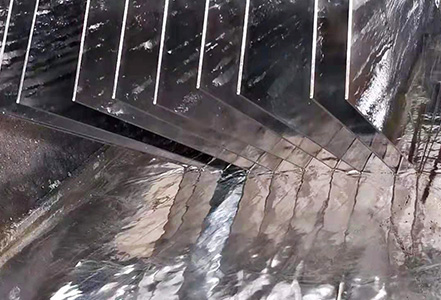

4. After the flux, the steel is dipped into a molten zinc bath for galvanizing

5. Check the finished product

Galvanized

Galvanized Galvanized coating inspection

Galvanized coating inspectionHot dip galvanizing standard

Hot-dip galvanized standard The technical parameters of hot-dip galvanized coatings on steel products are specified by a single standard, namely BS EN ISO 1461 “Hot-dip galvanized coatings on steel products – Technical parameters and test methods”. When the steel is hot-dip galvanized, the surface is completely covered with a uniform coating, and the thickness of the coating is mainly determined by the thickness of the galvanized steel itself (please refer to the table for details).

| Product thickness | Minimum zinc layer thickness | Minimum zinc layer thickness | ||

| g/m2 | μm | g/m2 | μm | |

| steel products>6mm | 505 | 70 | 610 | 85 |

| 3mm<steel products≤6mm | 395 | 55 | 505 | 70 |

| 1.5mm≤steel products≤3mm | 325 | 45 | 395 | 55 |

| steel products<1.5mm | 250 | 35 | 325 | 45 |

| steel casting≥6mm | 505 | 70 | 575 | 80 |

| steel casting<6mm | 430 | 60 | 505 | 70 |

| Rebar and round steel (textured steel products) Product thickness |

Minimum zinc layer thickness | Minimum zinc layer thickness | ||

| g/m2 | μm | g/m2 | μm | |

| diameter≥20mm | 325 | 45 | 395 | 55 |

| 6mm<diameter≤20mm | 250 | 35 | 325 | 45 |

| diameter≤6mm | 145 | 20 | 180 | 25 |

| Other products (including castings) | ||||

| diameter≥20mm | 325 | 45 | 395 | 55 |

| 6mm<diameter≤20mm | 250 | 35 | 325 | 45 |

Hot dip galvanized round tube

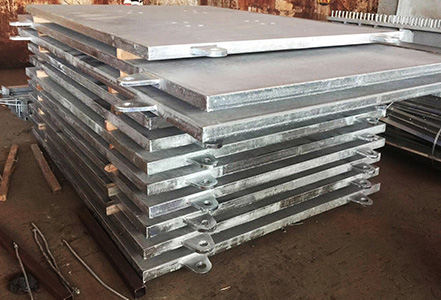

Hot dip galvanized round tube Hot dip galvanized steel sheet

Hot dip galvanized steel sheetGet Your Free Quotation Today!

HK HuangShangYou Steel Industrial Limited

HK HuangShangYou Steel Industrial LimitedEmail: king@ulsteel.com WhatsApp: +852-65561469 WeChat: +852-65561469

[contact-form-7 id=”2011″ title=”pr-contact”]

相關產品

2012-2026 HSY Steel All Rights Reserved.