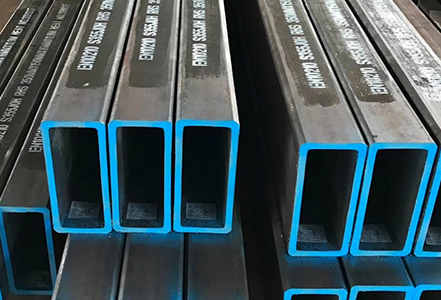

Ideal for structural applications, repair, and fabrication, hot-formed structural rectangular steel pipe is easy to cut, weld, form, and machine. It is also easier to bend than cold-formed rectangular steel pipe and can be used in curved framing. Hot rolled flat passes are also ideal for building unique and aesthetic structures without compromising strength, aesthetics and durability.

S235JRH Hot Formed Rectangular Steel Pipe:

Since S235JRH is a low carbon material, it can be welded without the risk of localized corrosion.

S275J0H Hot Formed Rectangular Steel Pipe:

As a variant of mild steel, the material transfers heat very well and does not crack under welding heat, making it suitable for high temperature and high pressure applications such as oil and gas, petroleum, petrochemical and boilers, and power plants.

S275J2H Hot Formed Rectangular Steel Pipe:

It has many characteristics such as easy molding, high tensile performance, durability and compact structure. For bridge and building structures, railings, vehicle frame structures, racks, tower cranes and cranes, etc.

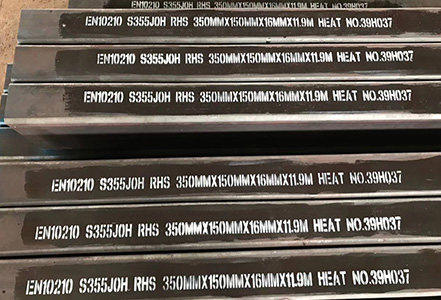

S355J0H Hot Formed Rectangular Steel Pipe:

High tensile strength, strong machinability and ability to withstand high loads. Used in various buildings and structures such as transmission towers, deep water projects, oil and gas projects, power plants, stations, seaport facilities, airport facilities, etc.

S355J2H Cold Formed Rectangular Steel Pipe:

It has many characteristics such as fine grain structure, uniform mechanical properties, high compression resistance, weldability, high cross-sectional performance, fire resistance, and negligible residual stress.

The available grades of rectangular steel pipes are EN, ASTM, GB and JIS.

The section size of the hot-formed structural rectangular steel pipe can reach 800mm and the thickness can reach 35mm. The normal supply length is 6m~12m, but other lengths of 4m~16m can be provided upon request. Additionally, other lengths are available upon request. This meets almost all international quality standards and undergoes various tests.

Steel pipe implementation standard:EN 10219-2 : 2006

Steel pipe material grade:S235JRH,S275J0H,S275J2H,S355J0H,S355J2H,S275NH,S420NLH,S420NH, IS 4923 / ASTM A500

Surface Protection: Black (Natural Uncoated), Clear/Oil Coated, Pre-Galvanized, Hot-Dip Galvanized

Metal slings are generally bundled into rectangles for storage and transportation.

European Standard BS EN 10219-1:2006

| size(D x B) | thickness(t) | unit weight |

| mm | mm | kg/m |

| 30 x 20 | 1.5 | 1.11 |

| 2.3 | 1.64 | |

| 3.0 | 2.07 | |

| 40 x 20 | 1.5 | 1.34 |

| 2.3 | 2.00 | |

| 3.0 | 2.54 | |

| 40 x 30 | 1.5 | 1.58 |

| 2.3 | 2.36 | |

| 3.0 | 3.01 | |

| 50 x 25 | 1.5 | 1.70 |

| 2.3 | 2.54 | |

| 3.0 | 3.25 | |

| 50 x 30 | 1.5 | 1.81 |

| 2.3 | 2.72 | |

| 3.0 | 3.41 | |

| 3.2 | 3.61 | |

| 4.0 | 4.39 | |

| 5.0 | 5.28 |

| grade | The chemical composition is not more than Max.(%) | |||||

| C | Si | Mn | P | S | N | |

| S235JRH | 0.17 | — | 1.4 | 0.040 | 0.040 | 0.009 |

| S275J0H | 0.20 | — | 1.5 | 0.035 | 0.035 | 0.009 |

| S275J2H | 0.20 | — | 1.5 | 0.030 | 0.030 | — |

| S355J0H | 0.22 | 0.55 | 1.6 | 0.035 | 0.035 | 0.009 |

| S355J2H | 0.22 | 0.55 | 1.6 | 0.030 | 0.030 | — |

| grade | The chemical composition is not more than Max.(%) | |||||||||||||

| C | Si | Mn | P | S | Nb | V | Al | Ti | Cr | Ni | Mo | Cu | N | |

| S420MH | 0.22 | 0.60 | 1.00~1.70 | 0.035 | 0.030 | 0.050 | 0.20 | 0.020 | 0.03 | 0.30 | 0.80 | 0.10 | 0.70 | 0.025 |

| S420MLH | 0.030 | 0.025 | ||||||||||||

| grade | Yield strength not less than Min.(N/mm2) | tensile strength(N/mm2) | |||||||

| t≤16 | 16<t≤40 | 40<t≤63 | 63<t≤80 | 80<t≤100 | 100<t≤120 | t≤3 | 3<t≤100 | 100<t≤120 | |

| S235JRH | 235 | 225 | 215 | 215 | 215 | 195 | 360~510 | 360~510 | 350~500 |

| S275J0H | 275 | 265 | 255 | 245 | 235 | 225 | 430~580 | 410~560 | 400~540 |

| S275J2H | |||||||||

| S355J0H | 355 | 345 | 335 | 325 | 315 | 295 | 510~680 | 470~630 | 450~600 |

| S355J2H | |||||||||

| S275MH | 275 | 265 | — | — | — | — | 360~510 | 360~510 | — |

| S275MLH | |||||||||

| S420MH | 420 | 400 | — | — | — | — | 500~660 | 500~660 | — |

| S420MLH | |||||||||

| grade | The elongation is not less than Min.(%) | Minimum impact energy KV(J) | ||||||

| t≤40 | 40<t≤63 | 63<t≤100 | 100<t≤120 | -50℃ | -20℃ | 0℃ | +20℃ | |

| S235JRH | 26(24) | 25 | 24 | 22 | — | — | — | 27 |

| S275J0H | 23(20) | 22 | 21 | 19 | — | — | 27 | — |

| S275J2H | — | 27 | — | — | ||||

| S355J0H | 22(20) | 21 | 20 | 18 | — | — | 27 | — |

| S355J2H | — | 27 | — | — | ||||

| S420NH | 19 | 19 | — | — | — | 40 | — | — |

| S420NLH | 27 | — | — | — | ||||

HK HuangShangYou Steel Industrial Limited

HK HuangShangYou Steel Industrial LimitedEmail: king@ulsteel.com WhatsApp: +852-65561469 WeChat: +852-65561469