Piling steel pipe products are widely used in wharf, natural gas pipeline, petrochemical, mining, electric power, coal chemical, marine engineering, infrastructure engineering, steel structure and water supply and other fields.

Huangshangyou Iron and Steel provides piling steel pipes, spiral steel pipes, sewage shaft steel pipes, piling steel pipes for civil foundation engineering, sea reclamation piling pipes, bridge steel pipe piles, construction steel pipe columns, steel pipe piles, etc., and stainless steel pipes for construction projects. And supporting the supply of 3LPE/3LPP, polyurethane, asphalt, and other forms of anti-corrosion steel pipes, welcome to inquire.

2. High bending strength, piling steel plate has high section stiffness and bending strength, and can resist considerable horizontal force in earthquakes.

3. The cross-sectional area of the pile is small, the excavation is less, and the vibration and noise are reduced.

4. It can be customized to adapt to various structures.

5. It is convenient to connect with the superstructure.

6. Light and strong, easy to handle and transport.

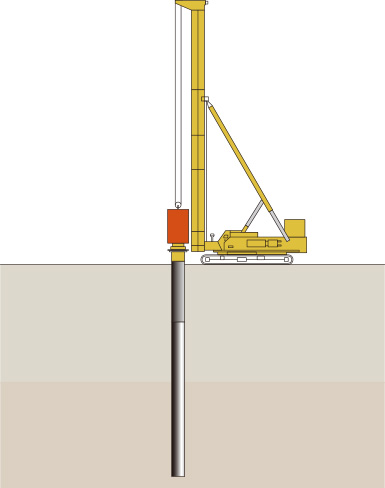

Digging method:

1. Pile driving 2. Check the verticality of the pile core

3. Excavation penetration 4. Penetration into the support layer

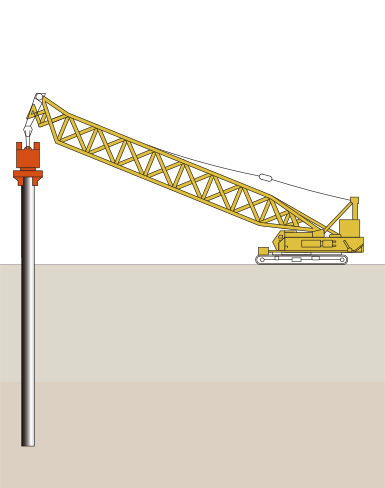

Vibration construction method:

1. Pile driving 2. Check the verticality of the pile core

3. Vibration immersion tube 4. Penetration into the support layer

2. 114mm~762mm (wall thickness 4mm-30mm) straight seam high frequency welded pipe (HFW)

3. 219mm~3000mm (wall thickness 8mm-90mm) spiral submerged arc welded pipe (SAWH)

4. 610mm~2500mm (wall thickness 24mm-90mm) three-roll forming welded pipe

5. 406mm~2000mm (wall thickness 16mm-60mm) stainless steel welded pipe

Steel pipe implementation standard:EN10210-2:2006 EN10219:2:2006

Steel pipe material grade:S275JRH S275J0H S355JRH S355J0H S355J2H S450J2H S550J2H S.S304 S.S316L S.S430

Large diameter steel pipe pile

Large diameter steel pipe pile 508×20mm steel pipe pile-S355J0H

508×20mm steel pipe pile-S355J0H 813×16mm steel pipe pile

813×16mm steel pipe pile Galvanized Steel Pipe Pile

Galvanized Steel Pipe Pile 275×12.5mm steel sheet pile

275×12.5mm steel sheet pile 610x12mm steel sheet pile

610x12mm steel sheet pileEuropean Standard BS EN 10219-1:2006

| outer diameter(D) | thickness(t) | unit weight |

| mm | mm | kg/m |

| 21.3 | 5.0 | 26.4 |

| 6.3 | 33.1 | |

| 8.0 | 41.6 | |

| 10.0 | 51.6 | |

| 12.5 | 63.7 | |

| 14.2 | 71.8 | |

| 16.0 | 80.1 | |

| 244.5 | 5.0 | 29.5 |

| 6.3 | 37.0 | |

| 8.0 | 46.7 | |

| 10.0 | 57.8 | |

| 12.5 | 71.5 | |

| 14.2 | 80.6 | |

| 16.0 | 90.2 | |

| 20.0 | 111 |

European Standard EN 10219-1 & 10219-1

| grade | The chemical composition is not more than Max.(%) | ||||||

| C | Si | Mn | P | S | Cu | N | |

| S235JR | 0.17 | — | 1.40 | 0.035 | 0.035 | 0.55 | 0.012 |

| S275JR | 0.21 | — | 1.50 | 0.035 | 0.035 | 0.55 | 0.012 |

| S355JR | 0.24 | 0.55 | 1.60 | 0.035 | 0.035 | 0.55 | 0.012 |

| S235JRH | 0.17 | — | 1.40 | 0.040 | 0.040 | — | 0.009 |

| S275J0H | 0.20 | — | 1.50 | 0.035 | 0.035 | — | 0.009 |

| S355J0H | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | — | 0.009 |

European Standard EN 10219-1 & 10219-1

| grade | Yield strength not less than Min.(N/mm2) | The tensile strength is not less than Min.(N/mm2) |

The elongation is not less than Min.(%) |

Impact test | energy Min.(J) | |

| t≤16 | 16<t≤40 | 0℃ | 20℃ | |||

| S235JR | 235 | 225 | 360 | 26 | — | 27 |

| S275JR | 275 | 265 | 410 | 23 | — | 27 |

| S355JR | 355 | 345 | 470 | 22 | — | 27 |

| S235JRH | 235 | 225 | 360 | 24 | — | 27 |

| S275J0H | 275 | 265 | 410 | 20 | 27 | — |

| S355J0H | 355 | 345 | 470 | 20 | 27 | — |

HK HuangShangYou Steel Industrial Limited

HK HuangShangYou Steel Industrial LimitedEmail: king@ulsteel.com WhatsApp: +852-65561469 WeChat: +852-65561469