Sheet piles are steel sheet sections with interlocking edges that are driven into the ground to provide permanent or temporary soil and water protection and excavation support. The load-bearing capacity of a sheet pile section depends on its geometry and the driven soil.

Steel sheet piles have two processes, hot rolling and cold bending. Hot-rolled steel sheet piles include U-shaped, Z-shaped, straight-web-type, etc., and cold-formed steel sheet piles usually include U-shaped, Z-shaped, Omega-shaped, and grooved plates. Hot-rolled and cold-formed sheet piles have similar properties and strengths.

The steel sheet piles are connected by interlocking, the gap between the two threaded interlocks is moderate, it has good resistance to high driving stress and excellent water tightness, and the length can be increased by welding or bolting. Hot-rolled sheet piles, also known as Larsen sheet piles, are produced from steel at high temperatures, so they tend to interlock more tightly and are more watertight than cold-formed sheet piles. The cold-formed steel sheet piles are light in weight and large in section modulus.

Advantages of sheet piles:

1. Resist high driving stress

2. Can be used multiple times in multiple projects

3. Can be used underwater or above the water surface, and has a long service life

4. Suitable joints can be provided to form a continuous wall, which can be built into almost any desired shape

5. Pile length can be increased by welding or bolting

Application of steel sheet pile:

1. Retaining walls, artificial islands, permanent retaining walls

2. Wharf, cofferdam

3. River bank protection

4. Retain the side section formed by the soil

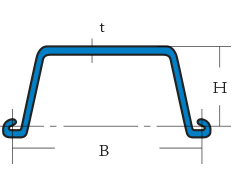

| Japanese Standard JIS A-5528 EN10248-1996 | |||||

| model | width(B) | high(H) | Waist(t) | Weight per unit length | Weight per unit wall width |

| mm | mm | kg/m | kg/m | kg/m² | |

| Type2 | 400 | 100 | 10.5 | 48.0 | 120 |

| Type3 | 400 | 125 | 13.0 | 60.0 | 150 |

| Type4 | 400 | 170 | 15.5 | 76.1 | 190 |

| Type6 | 600 | 210 | 18.0 | 106.2 | 177 |

| Standard | The chemical composition is not more than Max.(%) | |||||

| Grade | C | Si | Mn | P | S | |

| JIS A 5528 | SY295 | — | — | — | 0.04 | 0.04 |

| SY390 | — | — | — | 0.04 | 0.04 | |

| JIS A 5523 | SYW295 | 0.18 | 0.55 | 0.15 | 0.04 | 0.04 |

| SYW390 | 0.18 | 0.55 | 0.15 | 0.04 | 0.04 | |

| EN 10248 | S355GP | 0.24 | 0.55 | 1.6 | 0.04 | 0.04 |

| S390GP | 0.24 | 0.55 | 1.6 | 0.035 | 0.035 | |

| S430GP | 0.24 | 0.55 | 1.6 | 0.035 | 0.035 | |

| S460AP | 0.24 | 0.55 | 1.7 | 0.035 | 0.035 | |

| Standard | Grade | Yield strength not less than | The tensile strength is not less than | The elongation is not less than |

| Min.(N/mm2) | Min.(N/mm2) | Min.(%) | ||

| JIS A 5528 | SY295 | 295 | 490 | 17 |

| SY390 | 390 | 540 | 15 | |

| JIS A 5523 | SYW295 | 295 | 490 | 17 |

| SYW390 | 390 | 540 | 15 | |

| EN 10248 | S355GP | 355 | 480 | 22 |

| S390GP | 390 | 490 | 20 | |

| S430GP | 430 | 510 | 19 | |

| S460AP | 460 | 550 | 17 |

HK HuangShangYou Steel Industrial Limited

HK HuangShangYou Steel Industrial LimitedEmail: king@ulsteel.com WhatsApp: +852-65561469 WeChat: +852-65561469